Despite hazards associated with CO2 being commonly known throughout various industries, leading practices still are not enforced in every business resulting in tragic and avoidable accidents happening within the workplace each year.

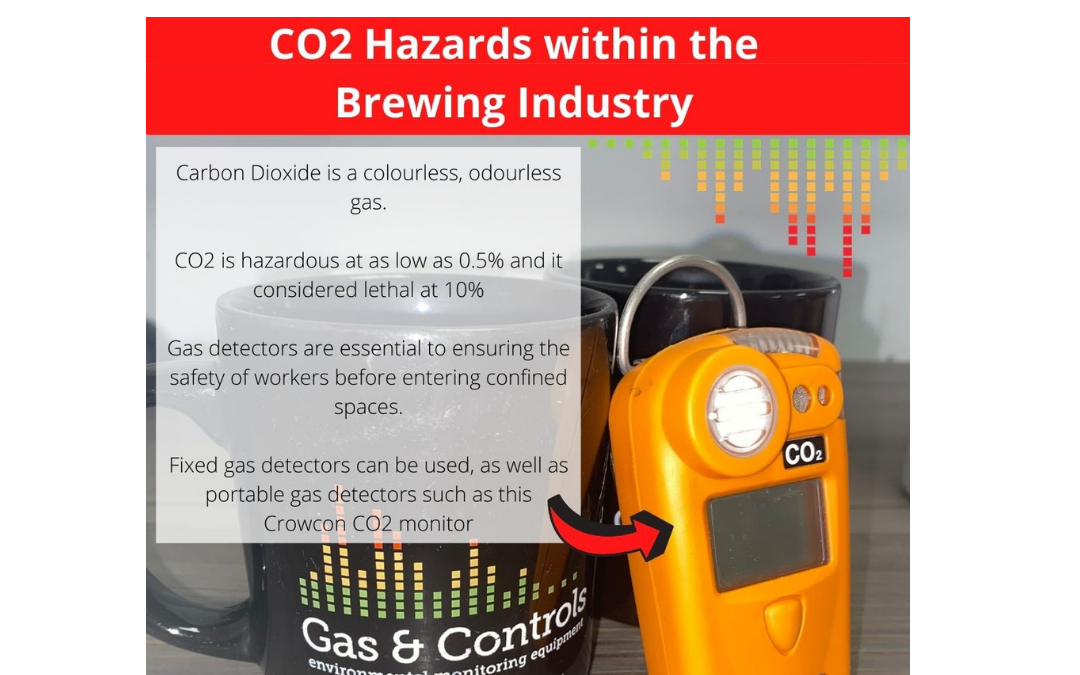

Enforcing prudent precautions can mean the difference between life and death. CO2 can kill a person in two ways; the displacement of oxygen leading to rapid asphyxiation, or as a toxin through inhalation. In both ways CO2 is deemed as hazardous at as low as 0.5%, and it is considered lethal when 10% or more is present and ultimately can lead to death. There is no physical indication of this gas as it is both colourless and odourless, therefore without the appropriate gear it is undetectable until it is too late.

Carbon Dioxide is a common by-product of the fermentation process within the brewing industry. Due to its molecular density, the gas typically collects at the bottom of confined spaces, including tanks and cellars, which could eventually leak out and sink into floors. When it sinks to the floor it can become dangerous through forming invisible pockets. CO2 is considered a hazard throughout the whole manufacturing process, beginning at the initial brewing process until the end stage of packaging.

Fitting the many confined spaces throughout the brewery, such as mixing tanks and silos should be top priority. Employers should assess the risks of the areas involved while ensuring best practices are enforced. In most scenarios gas detectors will be needed to monitor the atmosphere.

Such areas should only be entered by employees and only when necessary. When essential to enter these areas industry protocol should be followed in order to minimise unnecessary health and safety risks. The fermentation/ pressurised gas should be discharged directly into the open air via a ring main system, this will completely remove the carbon dioxide from the contained space. If your interior is unable to accommodate this, the has will need to be manually removed and diverted before entering.

A release measurement should be conducted using a suitable gas detector before entering a confined space assessing if the CO2 concentration is within the acceptable parameters. This assessment should be carried out by a trained personnel, usually by lowering the device into the chamber for a certain amount of time. For the results to be most reliable the equipment should be properly calibrated and tested, therefore it is extremely important to do this before use.

Audio/ visual alarms on each detector will trigger immediately when CO2 levels spike outside of the predefined conditions. A pre warning will occur when CO2 has a volume of 0.5% and an alarm will activate within 1-2%, this is industry standard.

There are two forms of gas detectors, portable and fixed which can be both be used in breweries. A fixed gas detector typically is made up of multiple heads which are connected to a control panel. If gas levels increase the extractor fans will be triggered simultaneously, added features such as beacons and sirens can alert nearby workers to vacate the premises.

Many areas which need to be monitored do not have sufficient space to accommodate a fixed system, therefore a compact portable device would be more satisfactory. This device should have a user friendly interface for simple operation and minimise any error. There are many detectors which accommodate multiple sensor configurations.

These devices could mean the difference between life and death so the importance of a quality detector that is both reliable and durable to critical. To identify the most suitable device a reflection on the environment it will be used in should be assessed. The device will need to be compact and impact resistant in order to be strong enough to support workers through their day to day roles.